Manufacturing

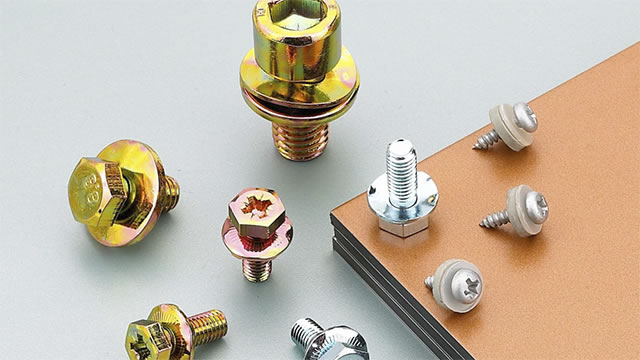

Zonfa’s raw material warehouse occupies a 500 m2 space and this is where there are several types and standards of wire rods, and washers for SEMS screws.

Since cold heading machines are major screw forming machines, Zonfa procured top quality cold heading machines from Taiwan, fully equipped with a computer monitoring system for use in real-time monitoring of the production process. Utilizing this method, we are able to test products in a very short time and avoid unnecessary waste and loss by quickly weeding out any defective items. Meanwhile, the cold heading machine also enjoys high precision, efficient operation and High quality.

Thread rolling machines operating in Zonfa workshops are also purchased from Taiwan and Japan. This machine coupled with precise molds provides excellent precision, stable quality and quick operation in the production of self-taping screws, thread rolling screws, and many others.

The combined thread rolling machine independently designed and developed by Zonfa inhouse, integrates both thread rolling and washer installation, which can install one to three washers simultaneously. So, when compared with traditional thread rolling machines, it enjoys a vastly greater working efficiency.

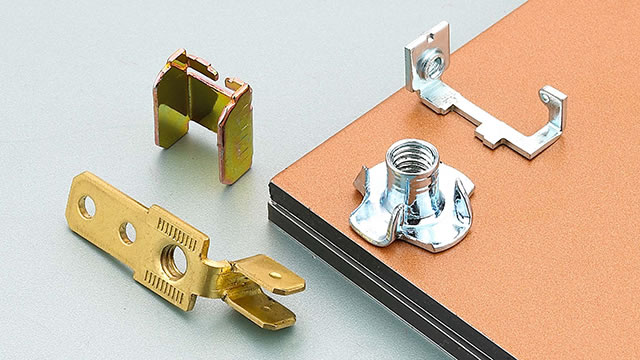

Our double stroke cold heading machine is introduced to rivet both silver and copper material for production of silver contacts. The machine is mainly applied in low-voltage electrical appliances, switches and many other fields.

The optical sorting machine also allows automatic appearance checking of fasteners. Therefore, after optical sorting, our fasteners will possess the finest quality and zero defects.

Kunshan Zhongfa Science Technology Hardware Co.,Ltd.

Add.: ZhongFa Road No.1, DianShanHu Town, KunShan, JiangSu, China

Postal code: 215343

Contact person: Ms. Lulu

Email: lulu@zfscrew.com

Tel.: +0512-55178888 Ext. 824

Mobile: +086-13912293253